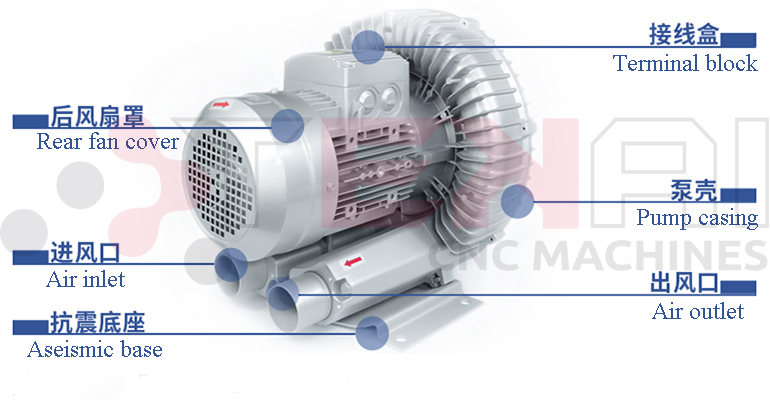

High pressure vortex air pump is engraving machine vacuum adsorption table necessary equipment, the use of vortex air pump suction to fix the cut, so that the cut in the cutting process is not offset, to ensure that the height of cutting accuracy!

High pressure vortex air pump configuration:

1. The casing material: the degree of die-casting aluminum, jinyi same aluminum die-casting aluminum and Benz car wheels, relative to the average aluminum alloy, aluminum die casting, in different form, the high pressure fan will have different effect, so the operation of the different forms, can also affect the effect of high pressure fan, fan, relative to the iron shell more lightweight. High pressure blower low shock, high wind pressure, small volume, light weight, low noise, high pressure, large air volume, no oil and gas, long service life.

2. Fan oil seal: the use of German oil seal, high-pressure blower impeller edge with a plurality of blades, when the air is re-introduced into the impeller by the air duct, will be accelerated again, relative to the general oil seal when the temperature of the lip is higher than the working medium temperature of 20~50℃, more stable performance, maintenance free, longer life.

3. Fan bearing: the core components are German and Japanese brand bearings, bearing temperature can withstand 350 degrees Celsius, 2800 RPM. For example, full wind vortex air pump, can also use suction and blow at the same time, equivalent to the same function of gas ring vacuum pump, for domestic roller shaft, human-oriented bearings, stable performance, low noise, free maintenance, longer life, fan can run for longer. The use of precision outer bearings and good heat dissipation, so it has many advantages.

High pressure vortex air pump use the maintenance

1. The vortex air pump should be placed in a stable place, the surrounding environment should be clean, dry and ventilated.

2. The direction of rotation of the impeller of the vortex air pump must be consistent with the direction of the arrow marked on the fan cover.

3. When the high-pressure vortex air pump works, the working pressure shall not be greater than 8kpa, so as not to cause excessive heat and motor supercurrent to cause damage to the air pump.

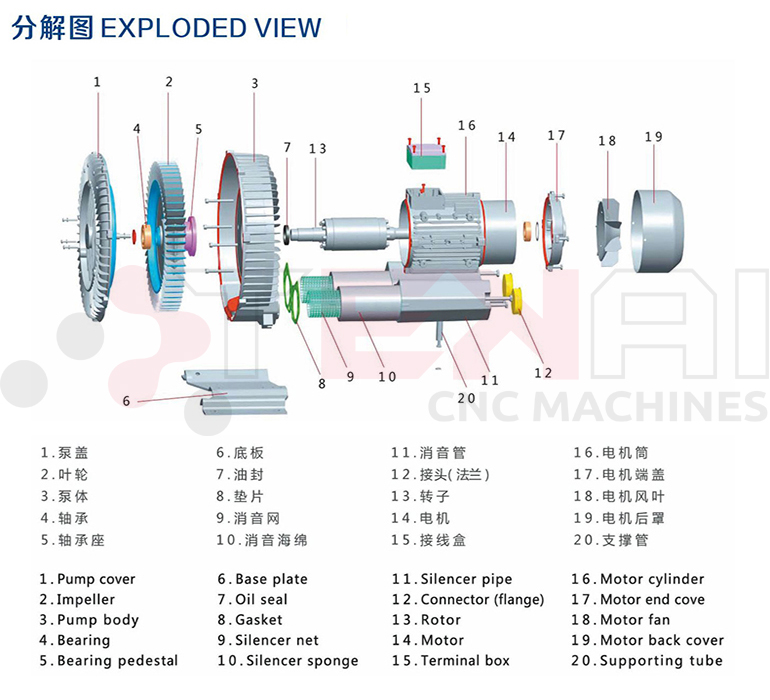

4. Vortex air pump in addition to the motor rotor two bearings, other parts have no direct contact friction. This air pump bearing installation mode is mainly divided into two types. The bearing at the end of the first type of air pump is installed in the pump body between the motor base and the impeller. This kind of air pump does not need to add grease at ordinary times. The second type of air pump end bearing is installed in the middle of the pump cover, this kind of air pump end bearing should be regularly added grease (7018 high-speed grease). Once a month, for three shifts of continuous work of the air pump should increase the number of refueling. This type of air pump motor fan end bearing maintenance according to the first type of air pump.

5. The filter screen and muffler device at both ends of the vortex air pump should be cleaned timely according to the situation, so as not to affect the use of blockage.

6. Vortex air pump inlet and outlet connection must be hose connection (such as rubber hose, plastic spring tube).

7. The replacement of vortex air pump bearings: the replacement of bearings must be operated by people familiar with repair work. First loosen the screws on the pump cover, and then remove the parts one by one in the order shown, the removed parts should be cleaned, and then assemble in reverse order. When disassembly, can not hard pry impeller, the application of special ramallah, at the same time do not omit to adjust the gasket, so as not to affect the factory has a good regulator gap.

8. High pressure vortex air pump is strictly prohibited from solid, liquid and corrosive gas into the pump body.

High pressure vortex air pump common problems and solutions

Vortex air pump in the conventional failure caused by high temperature and burning machine.

Fault phenomenon: the first motor can not start, even if no load can start, speed slowly rise, there is a buzz; The motor smoked and heated with a smell of burning. Remove the motor end cover, it can be seen that 1/3 or 2/3 of the polar phase winding at the end of the winding is coking or dark brown.

Main reasons:High pressure vortex air pump in the phase of operation

Solution:

1.The motor power supply loop fuse loop contact is bad or mechanical damage, resulting in a phase fuse fuse.

2.Motor power supply loop three-phase fuse specifications are different, the fuse with small capacity is burned off. Replace the fuse with the same specification according to the motor power.

3. The switches in the power supply circuit of the motor (isolation switch, plastic cover switch, etc.) and the contacts of the contactor are not in good contact (burned or loose). Repair and adjust the static and dynamic contacts to make good contact.

4. A phase of the line is missing. Find the broken line and connect it firmly.

5. Virtual welding between the motor windings leads to poor contact. Carefully check the motor winding connection line and weld.

Start from the details, according to the requirements of the standard operation and use, the machine can be used for a long time.

© Copyright - 2010-2025 : All Rights Reserved.

Hot Products - Sitemap - AMP Mobile