Customer satisfaction with the machine depends on the comfort of operation and the overall performance of the equipment.

The main elements of woodworking machinery cnc router design

1.Frame of Machine.

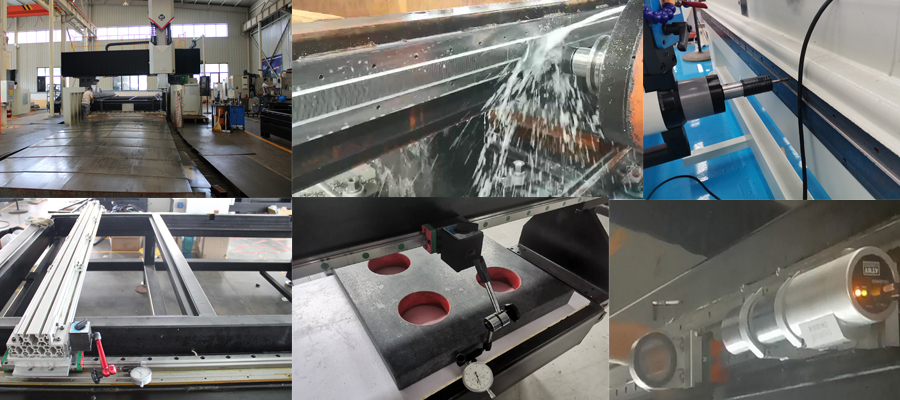

After the welding of the frame of Machine, the tension of the frame can be released and the change of the frame can be reduced. Then through large high precision gantry milling machine guide surface and rack surface milling and guide rack drilling and tapping, so as to ensure the maximum mechanical installation accuracy.

2.Spraying plastics

First frame line after sandblasting treatment, can deeply remove the rust on the surface of the frame and the more prominent solder joints, and then spraying plastics plastic powder through high voltage electrostatic equipment charging, under the action of the electric field, the coating will be sprayed to the surface of the workpiece, powder will be evenly adsorbed on the surface of the workpiece, the formation of powdery coating; The powdery coating is leveled and solidified after high temperature baking, and the plastic particles will melt into a layer of dense final protective coating,Firmly attached to the workpiece surface.The finished coating is highly resistant to chipping, scratches and other mechanical damage, effectively protects the metal parts from rusting and retains a neat appearance for a long time even when the machine is actively used.

3. The Gantry supports.

In the construction of the supports of gantry, the place of installation of linear bearings is as marked as possible. The upper platforms of the supports are expanded, equipped with amplifiers and after installation on powerful bolt connections make a single whole with gantry. The increased support base of the line bearings, combined with a rigid connection of supports and gantry, provides accurate and fast-speed operation of ATC CNC Router Machine.

4.Linear guide and rack

High-quality Linear guides are one of the most important design elements of the machine, responsible for accuracy and speed of processing.

Firstly, the straightness in horizontal plane of guide rail is detected by laser interferometer, and then the parallelism of two guide rails is measured by custom L-shaped measuring tool (including dial meter) to ensure responsible for accuracy and speed of processing during operation of the machine.

5. The layout of the control cabinet

The electronic part of the machine control consists of low-voltage and power equipment, high-frequency jamming sources and power lines. The correct location of all the items in the control cabinet ensures the stability of the equipment, eliminating the possibility of flooding and noise.

When installing control cabinets, we try to remove power and low-voltage elements from each other as much as possible. Thus, the frequency converter, which manages the spindle, is located in a separate compartment from the rest of the electronic equipment. High-voltage and low-voltage conductors are spread across different tires, and high-frequency or logical signals are transmitted through screened wires.

6.Electrical wiring

We use flexible wires that don’t get damaged by bending them multiple times. Special attention should be paid to the wiring terminals of each electrical component in the assembly of the equipment. There are about a thousand of these wire terminals in the machine, and each component has to be reliable. Ensure the safe operation of the machine.

7. Cable chains

The automatic 3d wood carving cnc router is fitted with high-section cable chains made of high-quality plastic, which does not dry out and does not become brittle after long operation. Each element of the chain is characterized by high strength and ensures the correct operation of the moving cable connections of the machine. The enlarged section of the cable chains makes it possible to put electrical conductors in them freely in order to prevent the erasure and formation of the halls.

8. Table material

To make the working surface of the table in production is introduced viniplast – a material made from primary raw materials. Its advantages have good chemical stability, corrosion resistance, hardness, strength, high strength, uv protection (aging resistance), fire retardant (with self-extinguishing), reliable insulation performance, smooth surface, no water absorption, no deformation, The fres used to align The machine’s work surface always remains sharp. Frasering takes place qualitatively, without excessive pressure, and, accordingly, without bending the material of the table between the cells of the mill during processing. Once aligned,the surface of the table remains “in the horizon” and does not compensate for the deflection gained from the tool’s push during processing.

9. The bearing grease system

The piping system provides a lubricant to all linear bearings and SVP nuts on the axis of the. To perform daily maintenance of the machine, it is enough to press the pump lever on the tank with oil. The ease of service contributes to the regular maintenance of the equipment, and accordingly its durability.

10. CNC system

We complete our wood door making cnc router cutting with three systems depending on the purpose of the equipment:

Taiwan LNC system is a simple, reliable and functional system, easily configurable for new hardware development and designed to replace the currently common remote systems to improve user performance for the operator and improve hardware performance. Mainly use high-end machines, such as: tool changing machines and loading and unloading machining centers , etc.

The Mach3 CNC control software is an open CNC system with simple operation, convenient maintenance, openness, stable performance, and a low-cost new CNC system. Because of its low-cost nature, ordinary cnc router 3 axis are mainly used.

The handle control system can be operated completely offline. After the handle reads the file from the U disk, it runs completely offline, which is simple and convenient to operate. Mainly suitable for computers and machines that are not in the same space

CONCLUSION

3d wood carving cnc router is a collection of many systems responsible for the correctness of its operation. Since there are no superfluous components in the machine, even a short-term failure of one of them or an error in the operation of any system can lead to its complete shutdown. If you buy a machine with errors in design, then in the future will have to spend a lot of time and money, endlessly turning to the service service of the supplier in order to eliminate the again and again manifesting shortcomings.

In short, only high quality machines can bring customer satisfaction and comfort.

© Copyright - 2010-2025 : All Rights Reserved.

Hot Products - Sitemap - AMP Mobile